High Quality Railway Bearings

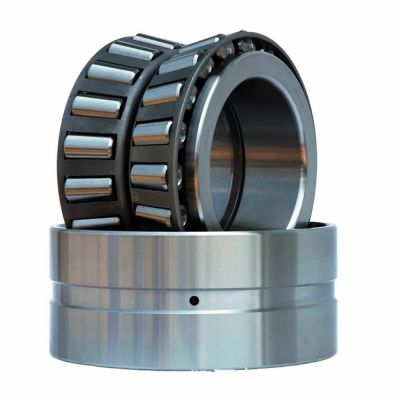

Railway bearings are a kind of bearings used on railways. Wheel axle bearing railway locomotive vehicle axle systems adopt different structural designs due to different application conditions. Locomotives and passenger cars have axle boxes, and the bearings are connected to bogies through axle boxes. Railway freight cars have no axles. The box and the bearing are connected with the side frame of the bogie through the bearing saddle. The bearings bear the shock loads that occur between the wheelset and the bogie frame, and also withstand the axial loads that occur when the vehicle turns. The axle bearing structure includes cylindrical roller bearings, cylindrical roller bearing units, tapered roller bearings, and tapered roller bearing units. According to the application requirements of railway bearings, axle bearings should have a long maintenance-free period, a structural design for easy maintenance and high reliability.

High Quality Railway Bearings

With the development of society, the railway machinery manufacturing industry continues to improve, and the relative railway bearing manufacturing technology is also constantly improving. The main function of the rolling bearing in the gearbox is to stably transmit the output torque when the locomotive is running at high speed, which means They must bear man variable impact loads in complex environments. Bearing types are mainly tapered roller bearings, four-point contact bearings and cylindrical roller bearings. Bearing configurations vary widely, mainly depending on the design and operating conditions of the gearbox.

The main application properties of bearings for gearboxes are:

1. High speed;

2. High load capacity;

3. Vibration and impact resistance;

4. High temperature resistance.

High Quality Railway Bearings Advantage:

Compared with sliding bearings, rolling bearings for railway wagons have the following advantages:

1. The friction coefficient of rolling bearings is small, which can improve the effective traction of locomotives. The friction coefficient of rolling bearings is much smaller than that of sliding bearings. Therefore, rolling bearings installed on railway freight cars can greatly reduce the starting resistance and running resistance of vehicles.

2. The safety of vehicle operation is improved. The bearing shell of the sliding bearing is in direct contact with the journal, the contact area is large, the wear is fast during operation, the heat is large, and it is not easy to dissipate. Therefore, it is easy to cause thermal shaft accidents; the rolling bearing is less worn, The calorific value is also small and easy to dissipate, so it can reduce the incidence of "hot shaft" and "eager" accidents and ensure driving safety.

3. Rolling bearings have high rotational speed and large carrying capacity. After railway wagons are equipped with rolling bearings, their loading weight and allowable running speed are significantly improved compared with those equipped with sliding bearings.

4. The maintenance time is shortened, the turnover of vehicles is accelerated, and the efficiency of vehicle use is improved. For vehicles using rolling bearings, the shaft inspection is canceled, the first-level repair process is reduced, and the maintenance cycle of railway wagons is extended. In general, rolling bearings are installed. When the truck is under maintenance, only the appearance inspection and rotation inspection are carried out on the rolling bearing. If there is no abnormality, it can continue to be used. The vehicle using the sliding bearing will directly affect the efficiency of the vehicle due to the frequent axle inspection and the long maintenance time.

5. Reduce the operating cost of railway wagons, save a lot of grease, white metal and other materials. Under normal use, the rolling bearings are only removed for general maintenance, return to the factory for overhaul or after the rolling bearings have been loaded and used for a specified number of years. For scrapped vehicles with sliding bearings, the axle inspection shall be carried out every 6 months, and the grease and bearing bush shall be replaced.

6. Easy to use and easy to maintain. The production and maintenance of rolling bearings have achieved specialization and standardization, and they are highly interchangeable. The adjustment, maintenance, lubrication, installation, and disassembly of bearings are very convenient. Therefore, rolling bearings are used in Widely used in railway vehicles.

The 353130B type bearing cancels the sealing seat; adopts the low-friction LL oil seal; installs a plastic steel spacer between the rear stop and the large end face of the inner ring of the bearing, eliminating the fretting abrasion on the contact surface between the inner ring and the back stop

Related News

Submitted successfully

We will contact you as soon as possible